10ton track one undercarriage

Kemer undercarriage is specialized company in designing, engineering and manufacturing side frames and complete undercarriage solutions conceived to satisfy the specific requirements of the customer.

Kemer is a dynamic and flexible company that prides itself on its ability to meet market challenges by providing a high-tech product in terms of design, innovation and quality,which can be replaced with track one undercarriage.

Advantage of Replaced Track one undercarriage

One of the most important advantages is that it offers a more competitive price for the same quality product. This means that customers can obtain high quality undercarriage components at a more affordable cost without having to sacrifice performance or durability. This cost-effective solution not only helps customers reduce machinery maintenance and operating costs, but also ensures the stability and reliability of their equipment!

How to measure and replace track undercarriage?

Measuring and replacing the track undercarriage of machinery, involves several detailed steps. Here's a concise guide to help you through the process:

Measure the Undercarriage

- Track Width: Measure the width of the track from edge to edge.

- Track Length: Measure the total length of the track around the sprockets.

- Pitch Measurement: Determine the pitch (distance between the centers of two consecutive track pins).

- Roller Diameter: Measure the diameter of the rollers for compatibility.

- Tension Adjustments: Check the tension on the track to ensure it is within manufacturer specifications.

Assess for Replacement

- Wear and Tear: Inspect for significant wear on the track and undercarriage components (e.g., sprockets, rollers).

- Visual Inspection: Look for cracks, bent components, or any signs of excessive wear.

Remove the Old Track

- Loosen Tension: Use the tension adjustment mechanism to loosen the track.

- Disconnect: If applicable, unbolt or detach the track links from the drive sprocket and loosen any securing devices.

- Slide off the Track: Carefully slide the track off and remove it completely from undercarriage components.

Track undercarriage introduction

Method: Hydraulic drive

Warranty: 12 months free

Weight: 2000kgs

Pallet size:2980*2200*720mm

Load capacity:10tons

Note: we can provide the following products value-added service

1.Independent development of domestic quantitative traveling motor or imported double speed motor can be freely selected.

2.Dimensions can be customized according to specific requirement.

3.Automatic rotary and manual rotation mechanism can be added.

4.Steel crawler chassis of all kinds of curved bridge angle are available.

5.Rubber pads for steel track are available to protect the road.

Technical parameters

|

|

Motor displacement ml/r |

Work pressure Mpa |

Traction force KN |

Travel speed km/h |

Ground pressure Kpa |

Max grade ability a° |

Dead weight kg |

Load capacity kg |

|

|

KST10000 |

62/39 |

25 |

116 |

2/3 |

51 |

30 |

2000 |

10000 |

|

Track undercarriage samples

Custom Your Undercarriage

Got your requirement for undercarriage

Make your undercarriage idea into reality

- Accurate Visualization: A 3D model provides a precise and realistic view of the chassis design, making it easier to understand complex structures and spatial relationships.

- Enhanced Design Flexibility: It allows engineers and designers to easily modify and optimize the chassis layout before physical production, saving time and resources.

- Improved Communication: A detailed 3D model serves as an effective communication tool among teams, clients, and manufacturers, ensuring everyone has a clear understanding of the design.

- Manufacturing Precision: It provides accurate data for CNC machining and other manufacturing processes, increasing production accuracy and efficiency.

Large enterprise scale

wide application of technology

high-quality customized services

Experienced Expertise

Over 20 years in undercarriage , our team provides reliable, professional support, ensuring projects are completed efficiently and to the highest standards.

advanced equipment

Using state-of-the-art equipment and technology, ensure the precise manufacturing, high quality, and consistency. Each chassis undergoes a walking test before leaving the factory.

professional team

Our expert assembly team guarantees accurate, efficient, and high-quality assembly, improving overall product reliability and reducing lead times.

one-stop solution

We offer comprehensive services from design and assembly, providing a complete, one-stop solution tailored to meet all your project requirements.

The Real Manufacturing Process Of Our Undercarriage

From Design To Production

Design and Planning

Based on customer requirements or standards, the chassis structure and technical specifications are designed and planned.

Raw Material Preparation

High-strength steel and related components are purchased, ensuring materials meet processing standards.

Forging and Machining

Critical parts such as hubs and pins are forged, turned, and milled to ensure precise dimensions.

Welding

Assembly

The chassis frame, brackets, and support wheels are welded together to form a complete structure.

Heat Treatment

Key welded parts undergo heat treatment to improve strength and wear resistance.

Surface Finishing

Painting and anti-corrosion coatings are applied to extend the chassis's lifespan.

Assembly

All components are assembled, including the track and wheel systems, followed by testing to ensure performance.

Quality Inspectio

Comprehensive inspections, including dimension checks, strength tests, and wear resistance, are conducted to ensure quality.

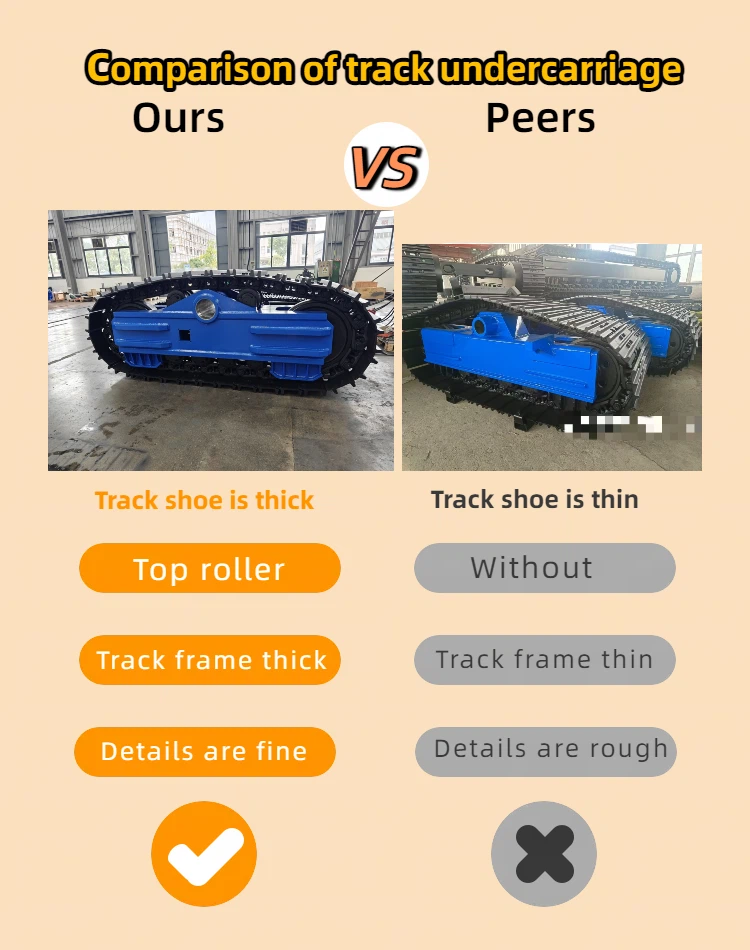

Why choose us?

Some competitors seek to cut expenses by opting for cheaper parts and reducing the overall build quality of their equipment. This often leads to a much shorter operational lifespan. A simple yet effective way to gauge the quality of such machinery is to ask for the total weight of the chassis. Generally, premium, durable components contribute to a heavier weight because they are made from better materials and constructed more robustly. On the other hand, a noticeably lighter chassis may suggest the use of lower-quality, less expensive parts. Conversely, a heavier chassis typically reflects the use of stronger materials and higher-quality construction, which usually means enhanced durability and a longer service life.

Thus, measuring the total weight of the chassis provides a quick and straightforward means to evaluate the construction quality and integrity of the equipment. It allows for more informed decision-making and helps identify whether competitors have taken shortcuts to reduce costs.

Wide Product Variety

Nearly 200 types, with customization options to meet various customer needs.

Professional Technical Team

Skilled professionals to provide expert support, resolving complex issues and ensuring customer satisfaction through continuous innovation and reliable solutions.

Reliable Product Quality

Built with durable materials and strict standards to ensure long-lasting performance and prevent shortcuts, giving customers confidence in the product's reliability and value.

Excellent After-Sales Service:

24/7 online support, one-year warranty, and lifelong maintenance.

Our Factory

Payment terms ,Delivery and Service

Payment:

30%deposit,70% before shipment.All the payment can negotiate, generally by T/T .

Delivery:

20-25 days after receipt of your payment.

Service:

24 hours online service, technical overseas service

Packing and shipping

FAQ

Q:How many square meters of your factory?

A:More than 16000 square meter.

Q:How many workers in your factory?

A:100 workers.

Q:What type of your product?

A:We are one of the most professional and biggest manufacturer of track undercarriage,hydraulic winch,planetary gearbox and travel drive in China.

Q: Where is your product use in?

A: In Drilling rig,Mechanical Engineering,Coal mine,Mine and Agricultural equipment,Mobile crane,Aerial platform,Wet spraying machinery,Pump truck,Thickener,Workover rig,Rolling machine etc.

Q:How to place order?

A:In order to recommend a suitable drawing and quotation to you,we need to know:

1.Rubber or steel track undercarriage

2.Loading capacity of the track undercarriage(The weight of the whole machine excluding of track undercarriage)

3.Length

4.Width

5.Height

6.Travel speed

7.Climbing capacity

8.System oil flow (each side of track undercarriage)

9.Working pressure

10.Order quantity

11.Used for which equipment

12.Road conditions

Hot Tags: track one undercarriage, China track one undercarriage manufacturers, suppliers, factory, Mst Undercarriage, Crawler Undercarriage, Skid Steer Track Loader, Undercarriage Assembly, Heavy Equipment Undercarriage, Crawler Track Undercarriage